Rolling Element Bearing Analysis

By Practicioners for Practicioners - Solutions That Work

Send us your rolling element bearings for a detailed and thorough independent analysis of the physical failure modes. We analyze the physical evidence, lubrication, design and installation practices. Our analysis will tell you what countermeasures may be taken to prevent future failures.

We have specified, installed and maintained thousands of rolling element bearings in a wide range of industries. Use our expertise to solve your bearing problems.

ISO Failure Modes – Clear, concise, and thorough analysis

- Rolling contact fatigue – surface or subsurface origin

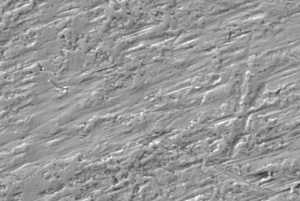

- Wear – abrasive and adhesive

- Corrosion – Moisture, fretting or false brinelling

- Electrical erosion – excessive voltage or stray current

- Plastic deformation – debris denting, overload or installation damage

- Fracture – overload, fatigue or thermal stress

Lubrication – Is it correct?

- Speed and load

- Contamination

- Temperature

- Viscosity and additives – suitability for speed, load and temperature

- Relubrication interval – amount and frequency

Design – What are the limitations?

- Radial and axial loads

- Parasitic loads

- Equivalent radial load and life

- Speed

Installation – Will it help maximize bearing life?

- Shaft and housing geometry and accuracy

- Shaft and housing fits

- Bearing internal clearance

Countermeasures – Steps that will help prevent future failures.

- Priortized by cost and effectiveness

- Optimize lubrication

- Installation methods

- How to minimize contamination

- Design for reliable operation